Industrial and commercial pump servicing & maintenance

24/7 emergency call-out service across Seaham, Durham, and the North

Repair, Don’t Replace

With a fully equipped workshop at our disposal, we can often provide a temporary replacement pump to minimise disruption to your operations.

A complete refurbishment or system overhaul can also lead to reduced energy consumption and help lower your environmental impact.

We can work on a range of pumps

- Axial flow

- Booster sets

- Centrifugal

- Dosing

- In-line circulating

- Multi-stage

- Self-priming

- Slurry

- Submersible

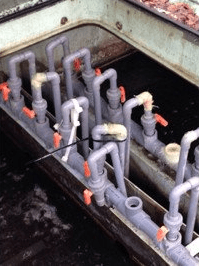

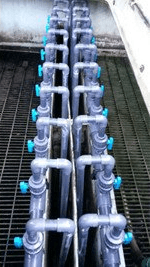

Comprehensive Repair and Refurbishment Services

We offer a full suite of repair and refurbishment solutions, including:

- Static and dynamic performance testing

- Mechanical repairs and reworking

- Electrical diagnostics and testing

- Motor rewinding, impeller servicing, rotor and dynamic balancing

- Gearbox repair and restoration

- Professional welding services

- Full flow testing and performance verification

- If your commercial pump is deemed uneconomical to repair, we can supply high-quality replacement units, carefully selected to enhance your current system’s performance.

Based in Seaham, we proudly support businesses across Durham, Sunderland, and throughout the North of England.

24-Hour Breakdown Support, Year Round

In the event of an emergency, our priority is to restore your peace of mind as quickly as possible. Our 24-hour call-out service ensures a rapid response from one of our experienced engineers, arriving fully equipped to deliver a swift and effective resolution.

Once the immediate issue is under control, we carry out a thorough assessment to determine the most practical, cost-effective solution tailored to your needs.

For emergency support, call our engineers directly on 07340 873591.

Decades of Experience in Pumping Systems

Whether for domestic, commercial, or industrial applications, Kelmec is a recognised and efficient team of pump and drainage specialists, ready to meet all your system requirements. Available 24 hours a day, we provide everything from initial design and full installations to refurbishments and commissioning — all delivered to the highest standards.

Our dedicated workforce and customer-focused management approach are designed to meet your every need. As a northern service contractor for a northern service partner, we deliver excellent value across a wide range of products. By fostering strong relationships with multiple supply chains, we’re able to manufacture and offer comprehensive packages tailored to our customers.

Our philosophy is simple: keep our customers satisfied by providing high-value, reliable solutions. We pride ourselves on being open, honest, and committed to delivering quality service at every stage.